The right solution for every requirement

Materials

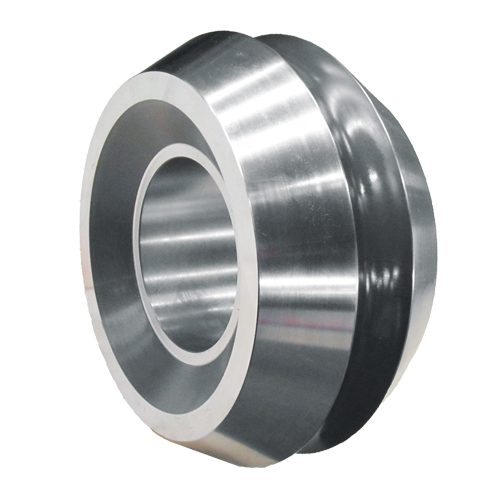

High-alloy standard for guide rollers

HDW 1 - Chrome strong for maximum service life

HDW 1 is the standard material for many of the guide rollers we manufacture. With a chromium content of almost 20 %, it has a significantly higher alloy than standard tool steel and achieves a significantly longer service life. The high chromium content creates a lubricating effect, which has a positive effect on the surface structure due to smooth surfaces and low wear.

- Areas of application: Guide rollers, cutting wheels

- Hardness: 52-61 HRc

The bridge between high-speed steel and spheroidal graphite cast iron

HDW 3 - Caliber service life redefined

This material closes the gap between our high-speed steel and tool steel alloys as well as ductile iron alloys. A slightly improved service life is the result of such technology.

- Areas of application: Tube rolling

- Hardness: 56-60 HRc

Our all-rounder for the highest demands

HDW 5 - Versatile, wear-resistant, machinable

HDW 5 is the most commonly used HDW material. With approx. 33 % alloy content, HDW 5 impresses with its long service life and low wear. Due to its hardness of up to 60 HRc, it is also very easy to operate.

- Areas of application: Tube rollers, wire rollers, guide rollers, rollers for Duo rolling stands

- Hardness: 56-60 HRc

Heat-resistant and economical

HDW 6 - Efficiency meets performance

HDW 6 is a lower alloyed variant of HDW 5. By reducing the alloy components by around 5 %, a good price-performance ratio is achieved with a similar tool life.

- Fields of application: Tube rollers, wire rollers, rollers for Duo rolling stands

- Hardness: 56-60 HRc

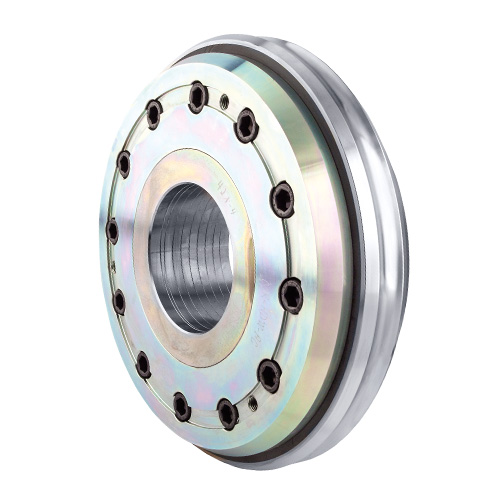

For maximum hardness and service life

HDW 7 - The choice for extreme loads

The high hardness of up to 66 HRc significantly increases the service life of the rollers. This variant is frequently used as a caliber roller and drive ring.

- Fields of application: Drive rollers, straightening rollers, tube rollers, wire rollers

- Hardness: 60-66 HRc

Heat-resistant and economical

HDW 8 - The alternative to carbide

With an alloy content of almost 40 %, this HDW alloy is the specialist when it comes to heat-resistant applications. This material has proven its worth, particularly for larger dimensions and slow rotation speeds, and offers a cost-effective alternative to carbide.

- Fields of application: Wire rollers, rollers for Duo rolling stands

- Hardness: 56-60 HRc