HDW materials

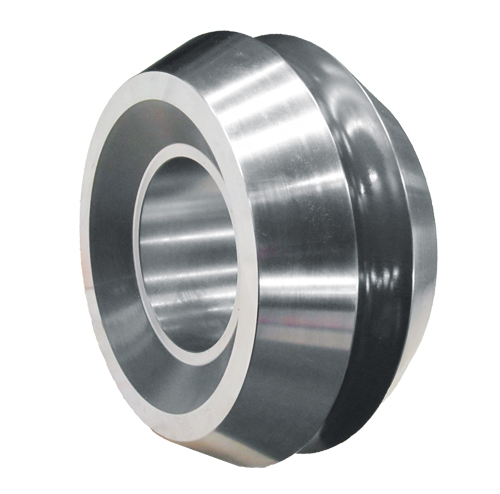

HDW 1:

This is the standard material for many guide roller manufactured by us. With a chrome component of almost 20%, it is a significantly higher compound than conventional tool steel and achieves significantly greater tool life.

The high chrome component has a lubricating effect, which has a positive effect on the surface structure due to the smooth surfaces and minimum wear.

Previous range of application: guide rollers, cutting wheels, etc.

Usual application toughness: 52-61 HRc

HDW 3:

This material closes the gap between our high-speed steel and tool steel alloys and spheroidal graphite alloys.

The advantage is a significantly improved calibre life.

Fields of application: tube expansion

Hardness: 56-60 HRc

HDW 5:

The most commonly used HDW material. With approx. 33% alloy components, HDW5 impresses with long tool life and minimum wear and tear. Due to the hardness of up to 60 HRc, it also has excellent cutting properties.

It is also very suited for the application in three-roller scaffolds (Kocks + SMS - Systems)

Scopes of applications: tube expansions, wire rollers, guide rollers, rollers for dual roll stands

Hardness: 56-60 HRc

HDW 6:

This is a lower alloyed variation of HDW5. The reduction of the alloying constituent by approx.

5% achieves a good price/performance ratio with a similar tool live.

Scopes of applications: tube expansions, wire rollers, rollers for dual roll stands

Hardness: 56-60 HRc

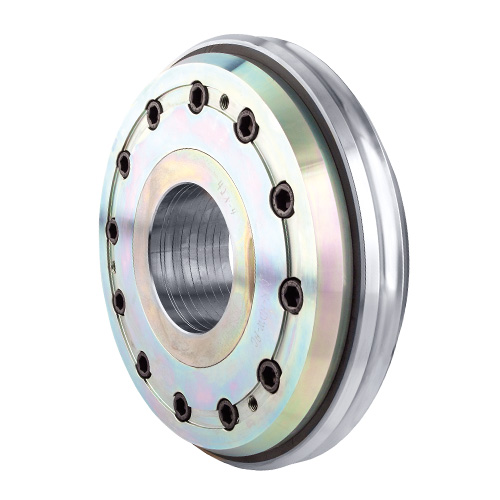

HDW 7:

The high hardness of up to 66 HRc significantly increases the tool life of the rollers.

This variation is often applied particularly as calibre roll or drive ring.

Scopes of applications: drive rollers, straightening rollers, tube expansions, wire rollers

Hardness: 60-66 HRc

HDW 8:

With an alloy content of almost 40%, this HDW alloy is the specialist in all heat-resistant applications. This material has proven its worth particularly with larger dimensions and slow circulation velocities and provides an inexpensive alternative to carbide.

Previous scopes of applications: wire rollers, rollers for dual roll stands

Hardness: 56-60 HRc